Fenwal Heat Detectors

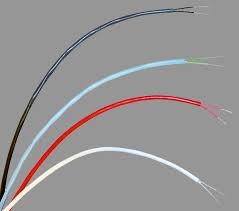

Kidde Fenwal Heat Sensor Cable

Notifier Addressable Detectors

Notifier FSV-951 Early Warning Detector

Notifier Conventional Detectors

Explosion Proof Smoke Detector

Vesda OSID FS-OSI-RI(A) Addressable Reflective Beam Smoke Detector

Li-Ion Tamer

Notifier Horn/Strobes

Kidde Horns & Strobes

Notifier Addressable Modules

Kidde Fenwal SmartOne Devices

Notifier Pull Stations

Kidde Fire Suppression Devices

Vesda Air Sampling

XAS Vesda Air Sampling Smoke Detector

Honeywell FSL100 Flame Detector

Fire Sentry UV/IR

Honeywell Gas Detection

THERMOFLEX Heat Detector

Potter Conventional Smoke Detector

Kidde Fenwal Smoke Detectors

MEDC Series XB11 Strobe

Kidde Fenwal Air Sampling

Power Sonic Batteries

Smoke & Fire

Alarm Devices

Alarm Devices

Kidde Fenwal Heat Sensor Cable

Kidde Fenwal LHS Linear Heat Sensor cable is a flexible, durable and cost-effective fixed temperature fire detector, suitable for protecting a wide range of commercial and industrial fire applications where spot-type heat detectors are unsuitable. Simple and easy-to-install, the LHS cable connects directly to the fire alarm panel initiating circuit. A short circuit along the LHS cable indicates a zone alarm condition. The LHS cable is available in a variety of operating temperatures and jackets.

Fixed temperature digital heat detector

Four alarm temperatures available: 155°F, 190°F, 220°F, 356°F

Compatible with all fire control panels

Connect directly to initiating circuit

Cost-effective solution for hazardous locations

Ideal for sse in applications where spot-yype heat detectors are unsuitable

Features: